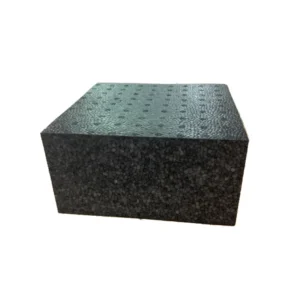

Our Custom Molded EPP (Expanded Polypropylene) Packing Boxes represent the industry standard for high-level protective packaging. Engineered for the most delicate electronics, medical devices, and industrial components, these boxes provide exceptional energy absorption and multi-impact resilience. Unlike traditional single-use packaging, EPP maintains its structural integrity and cushioning properties even after repeated drops and heavy vibrations. With nearly 30 years of manufacturing expertise, we offer a comprehensive bespoke service—including professional 3D structural modeling, custom mold development, and optimized material density—to help global manufacturers eliminate transit damage and enhance their brand’s sustainable packaging profile.

Key Features

-

Unrivaled Shock Absorption: The closed-cell EPP structure provides elite cushioning that dissipates kinetic energy, protecting sensitive internal components from severe impact.

-

Precision Molded Geometry: Custom-designed to the exact dimensions of your product, ensuring a perfect “lock-fit” that prevents shifting and abrasion during international logistics.

-

Ultra-Lightweight Durability: Significantly reduces total package weight compared to wooden or heavy plastic alternatives, optimizing airfreight costs while maintaining industrial-grade strength.

-

Eco-Friendly & Reusable: 100% recyclable and designed for a long service life. Its high chemical and moisture resistance makes it ideal for circular economy logistics.

-

Anti-Static & Thermal Protection: Available with anti-static additives (ESD safe) and inherent thermal insulation properties to safeguard electronics from both static discharge and temperature fluctuations.

| Specification Item | Details / Value |

|---|---|

| Product Name | Custom Molded EPP Packing Box |

| Material | Expanded Polypropylene (EPP) Foam |

| Density Range | 20g/L – 120g/L (Bespoke for specific load requirements) |

| Industrial Use | Electronics, Medical Devices, Automotive Parts, Aerospace |

| Customization | Full 3D Mold Design, Color Options, Logo Embossing |

| Performance | Multi-impact recovery, Waterproof, Chemical Resistant |

| Safety | Anti-static (Optional), Non-toxic, Halogen-free |

| Certificates | ISO9001, RoHS, REACH, SGS |

| Origin | China |

| Policy Item | Details |

|---|---|

| Design Service | Professional CAD/3D structural design and prototype sampling |

| Sampling Service | CNC-cut prototypes or pilot mold samples (7-14 days) |

| Trade Terms | FOB, CIF, EXW via Sea or Air Freight |

| Payment Terms | T/T, L/C, Trade Assurance |

Why Choose Us?

-

Decades of Manufacturing Excellence: With nearly 30 years of expertise since 1997, we are a leading authority in precision EPP molding and high-performance protective packaging.

-

Modern Large-Scale Infrastructure: Our 30,000 m² state-of-the-art facility is equipped with the latest high-pressure molding machines to ensure consistent quality for global supply chains.

-

Integrated R&D & Design: Our dedicated team specializes in material innovation and cushioning engineering, optimizing every box for maximum safety and material efficiency.

-

Strategic Logistics Advantage: Located near major shipping hubs, we provide streamlined customs handling and cost-effective delivery routes for our international clientele.